Google Glass AirTour Design

2016.05 - 2016.10 | UX Design | Workflow | Siemens, Princeton NJ

Problem

Siemens AG is a German conglomerate company headquartered in Berlin and Munich and the largest manufacturing and electronics company in Europe with branch offices abroad. There are lots of energy, automation, driven technology and building projects that Siemens involved and maintained in all over the world.

Among these large industrial projects, some building and maintenance work are very dangerous, such as wind turbine, power plant. Workers have to work in a small space and finish the precision but complex work. Thus, the maintenance fee is very high as well. In this case, Siemens wants to find out a new way to solve this problem using Google Glass to do remote work tutorial in order to save the cost.

Interview and Workflow Defined

Face to face interview

We came to French to interview the workers in Siemens Power Plant. The workers tell us that they want to use technology device to guide them during work but meanwhile they cannot use hands to hold the device. Therefore the Google Glass is the best choice for them.

Workflow Defined

Compare with our daily use cases, the industry work is much more complex and delicate - it requires that workers cannot do anything wrong in every step. Therefore, we worked with the industry workers in a week, asked them any questions, observed their daily work and used camera to shoot videos and photo for study research.

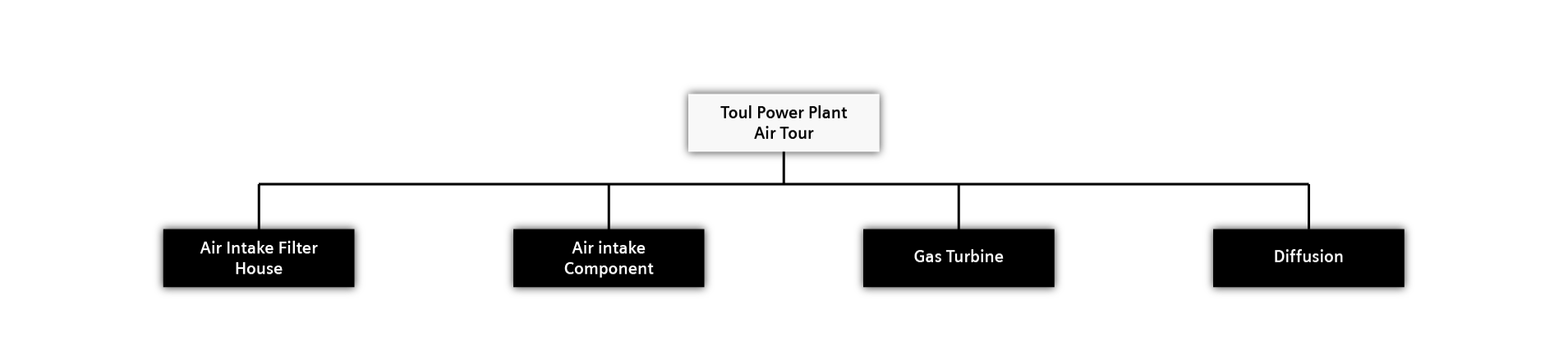

After we came back from study trip, we defined the workflow and use cases based on Google Glass Platform. The Power Plant workflow can be divided by four main subjects. In each subject, the workers need to check, fix and finish a serious of tasks given by Google Glass. If they face anything hard to solve by themselves, they can ask for help from remote experts using Real-Time Communication function (RTC).

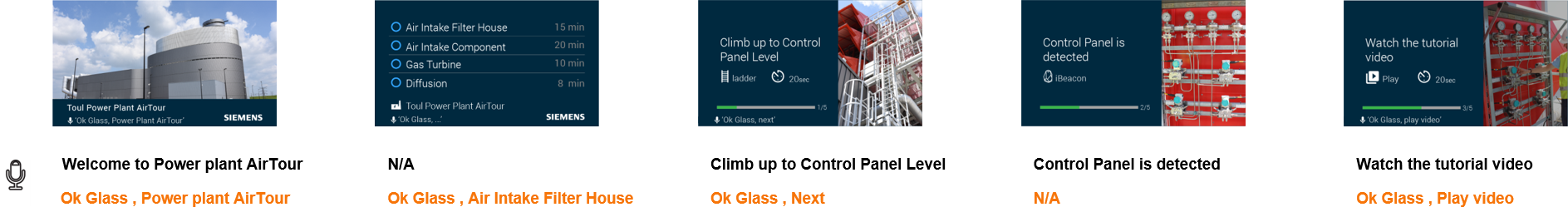

Toul Power Plant Air Tour Case in French - workflow part

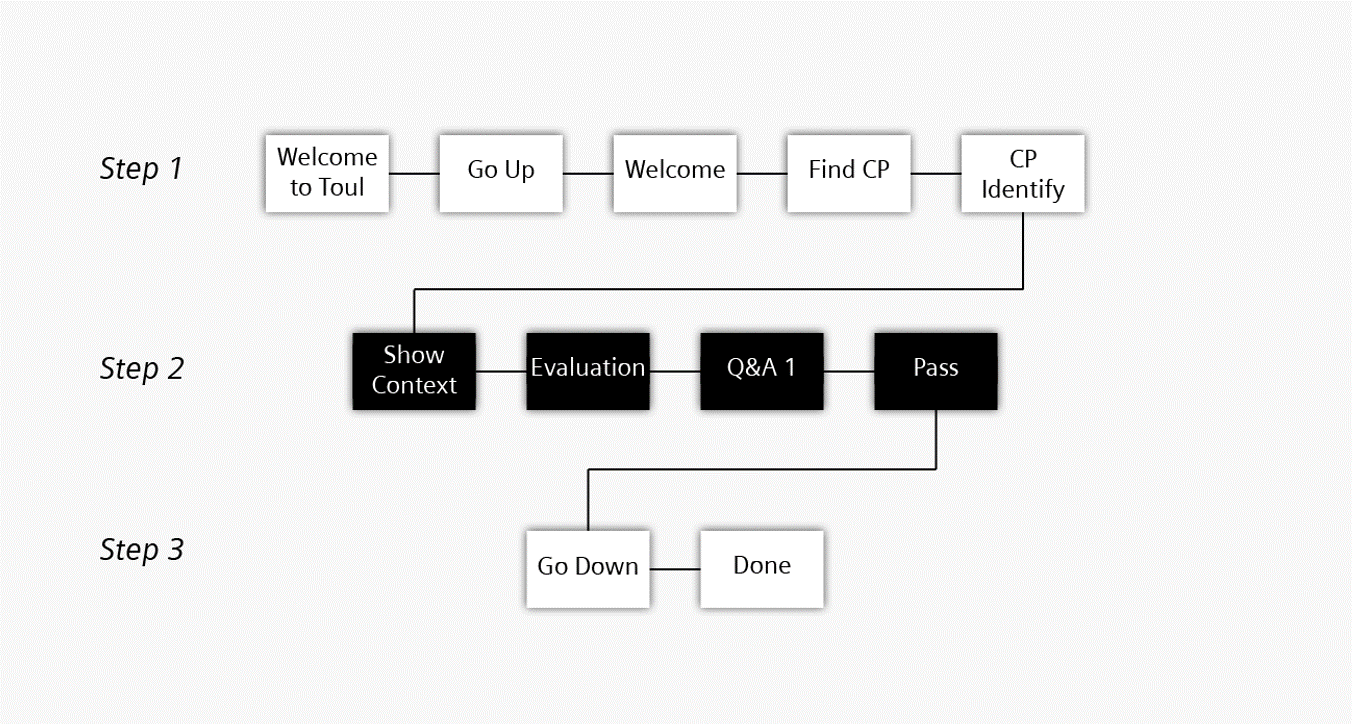

Task workflow in Subject 1

Mixed-Tech Design Solutions

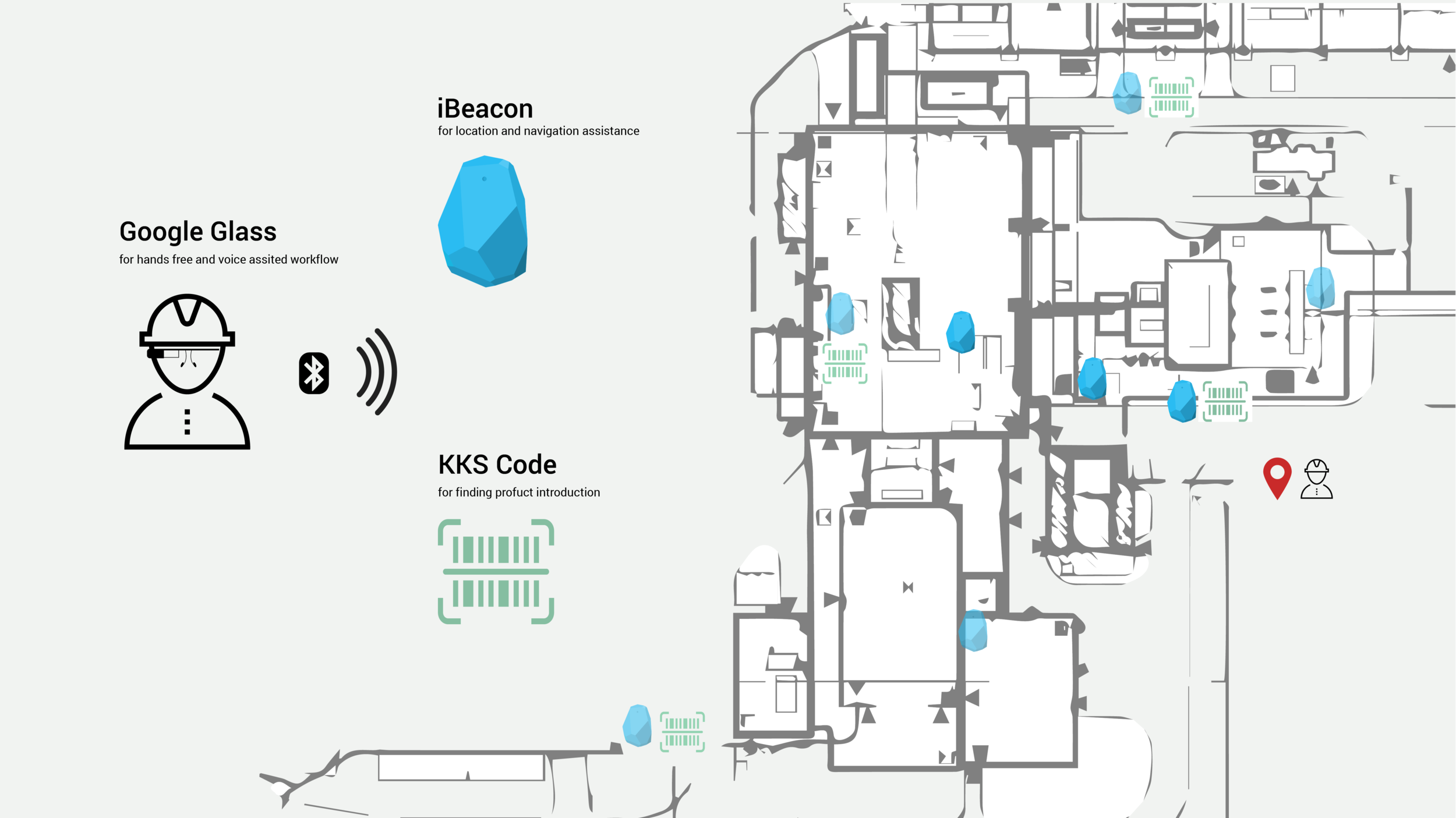

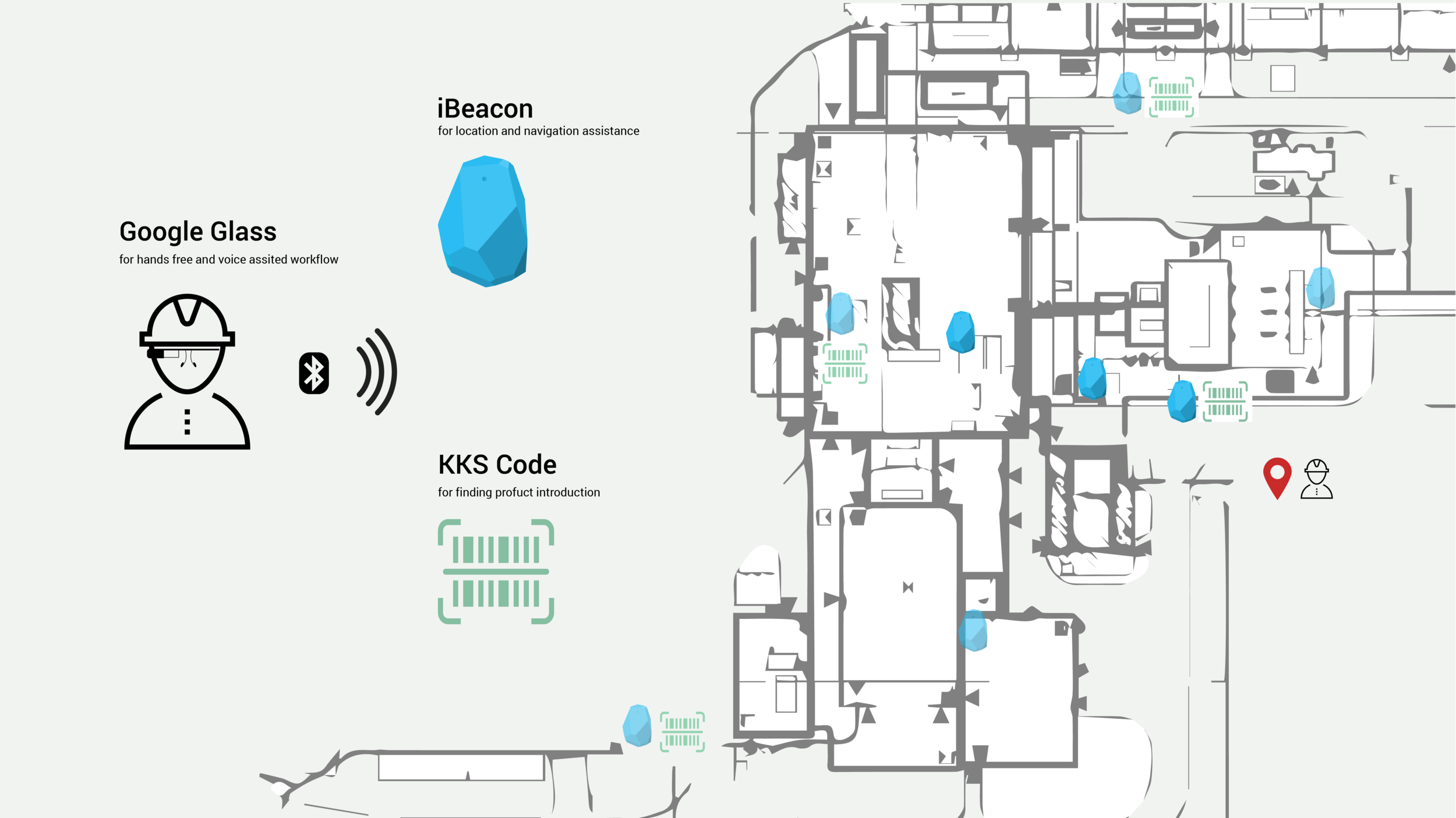

iBeacon Tracking

One of the problems we faced initially is location tracking. Because the power plant is a close, large, protected environment, workers cannot use GPS to locate their position. Therefore, we decided to use iBeacon for road and task guiding. We put iBeacons in specific places in the power plant and used Bluetooth to connect them with Google Glass. Thus, the workers won't miss the working task and their location in power plant.

iBeacon position diagram

Voice Interaction Control

Another problem we feel difficult is interaction. In the real work case, workers need to check and fix the delicate, complex industry machine so that they are not hand-free. However, they still need to interact with mobile device to guide them finishing the work. Therefore, all commands' interacts on Google Glass are done by voice interaction. Workers can "talk" to Glass and fix the machine at the same time.

Voice Interaction Design Part

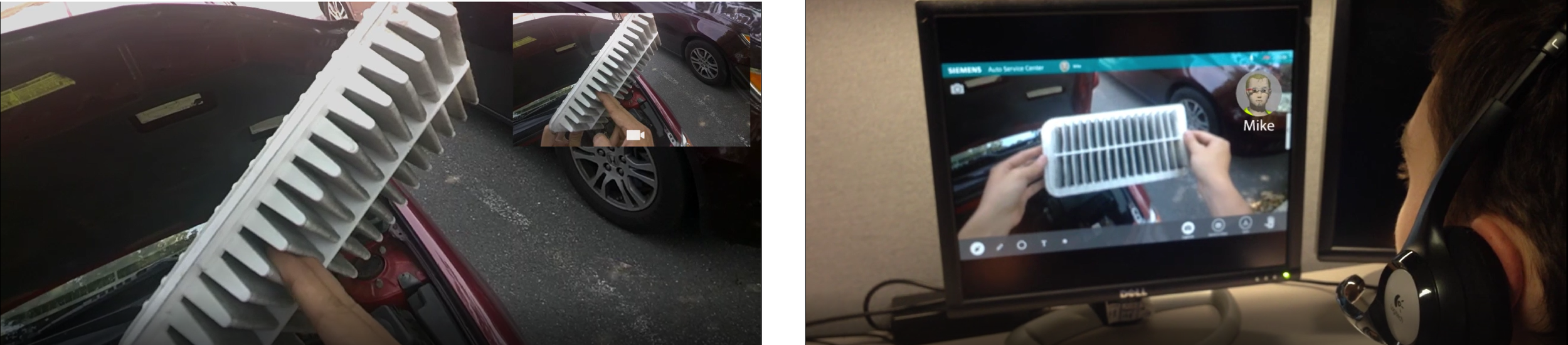

Remote Collaboration

The last difficulty we faced is the remote communication. Sometimes, the broken machines are very complex and normal workers cannot fix by themselves. Previous, workers always need to mark the issues down and report to experts. Then the experts will come from other places to the power plant and fix the issues. Therefore, we design the remote collaboration interface based on Google Glass so that worker can directly "Skype" with expert to solve problem issues through Google Glass.

Real-Time Communication Tech (Google View and Expert View)

Delivered Prototype

The project was finished in summer 2016 and was delivered in autumn 2016 with the developed beta version and short video demo.

Final Delivered Demo Workflow Part